As a producer of gasket material, a very common question we get asked is some variation of “How can you cut this?”. It is a great question, and one that should be asked before you even attempt to cut your first gasket out. Different types of material call for different cutting technologies. Some material is universal enough to be cut on just about anything, and other material can really only successfully be cut a certain way. There’s no need to struggle through a long period of trial and error…just keep reading to narrow your list of technologies to try.

As a producer of gasket material, a very common question we get asked is some variation of “How can you cut this?”. It is a great question, and one that should be asked before you even attempt to cut your first gasket out. Different types of material call for different cutting technologies. Some material is universal enough to be cut on just about anything, and other material can really only successfully be cut a certain way. There’s no need to struggle through a long period of trial and error…just keep reading to narrow your list of technologies to try.

Rule Die

Steel rule dies are the most common form of “die cutting”. They have worked extremely well cutting “soft” materials such as rubber, foam, cork, fiber, and others for many years. Metal-reinforced materials are also commonly cut with steel rule dies, sometimes with different rule, ejection rubber, and matting material.

Waterjet

Waterjet cutting works well with many homogeneous materials. For perforated (tanged) core products, it can be a challenge, as the water stream changes direction when hitting the core, resulting in blow-off, which removes the facing. For solid core items, waterjet cutting works well.

Laser Cut

Laser cutting has proven to be an excellent process to cut metal-reinforced materials. It works in most cases, except where a layered facing is used, where high heat can peel layers. Cutting graphite with a laser is possible, but takes some practice and adjustment to get a clean cut.

Hard Tool

Hard tooling is also called Class A dies or matched male/female tooling. This is the best method of cutting anything, and provides a clean cut with crisp edges and minimal deformation of the product. It is the best method for cutting metallic products in high volume.

Flash Cut

Flash cutting features a programmable, oscillating knife blade cutter on a bed-type table. This method works very well for small volume production of any size part, and is especially preferred for large parts in lieu of building a cutting die. Most materials cut well with this method, even metal-reinforced items of tang or solid core, except for Armor-clad designs.

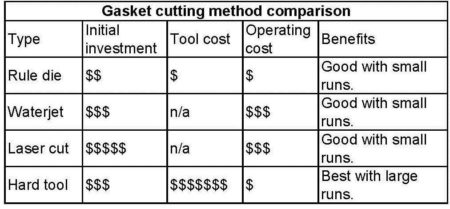

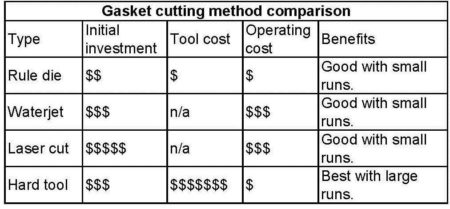

Thanks, But What’s the Cost?

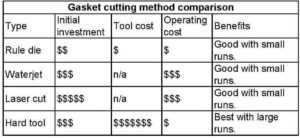

Since we’re not a fabricator, we aren’t in a position to tell you how much it actually costs to cut with these methods, but we do have a fairly good idea of where they fall on the scale from relatively inexpensive to relatively expensive. However, remember that it is important to look at value, not cost. (The same principles hold true – be sure to read How Much Should Gasket Material Cost?.)

Cut It Out!

There are a lot of great technologies out there and we’ve seen success with all 5 of these in different materials on our product line. If you don’t produce your own gasket material, one of the most important things you can do is ask your gasket material supplier how they would recommend you cut the material. It sure beats wasting time and precious material!

Happy Cutting! If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

As a producer of gasket material, a very common question we get asked is some variation of “How can you cut this?”. It is a great question, and one that should be asked before you even attempt to cut your first gasket out. Different types of material call for different cutting technologies. Some material is universal enough to be cut on just about anything, and other material can really only successfully be cut a certain way. There’s no need to struggle through a long period of trial and error…just keep reading to narrow your list of technologies to try.

Rule Die

Steel rule dies are the most common form of “die cutting”. They have worked extremely well cutting “soft” materials such as rubber, foam, cork, fiber, and others for many years. Metal-reinforced materials are also commonly cut with steel rule dies, sometimes with different rule, ejection rubber, and matting material.

Waterjet

Waterjet cutting works well with many homogeneous materials. For perforated (tanged) core products, it can be a challenge, as the water stream changes direction when hitting the core, resulting in blow-off, which removes the facing. For solid core items, waterjet cutting works well.

Laser Cut

Laser cutting has proven to be an excellent process to cut metal-reinforced materials. It works in most cases, except where a layered facing is used, where high heat can peel layers. Cutting graphite with a laser is possible, but takes some practice and adjustment to get a clean cut.

Hard Tool

Hard tooling is also called Class A dies or matched male/female tooling. This is the best method of cutting anything, and provides a clean cut with crisp edges and minimal deformation of the product. It is the best method for cutting metallic products in high volume.

Flash Cut

Flash cutting features a programmable, oscillating knife blade cutter on a bed-type table. This method works very well for small volume production of any size part, and is especially preferred for large parts in lieu of building a cutting die. Most materials cut well with this method, even metal-reinforced items of tang or solid core, except for Armor-clad designs.

Thanks, But What’s the Cost?

Since we’re not a fabricator, we aren’t in a position to tell you how much it actually costs to cut with these methods, but we do have a fairly good idea of where they fall on the scale from relatively inexpensive to relatively expensive. However, remember that it is important to look at value, not cost. (The same principles hold true – be sure to read How Much Should Gasket Material Cost?.)

Cut It Out!

There are a lot of great technologies out there and we’ve seen success with all 5 of these in different materials on our product line. If you don’t produce your own gasket material, one of the most important things you can do is ask your gasket material supplier how they would recommend you cut the material. It sure beats wasting time and precious material!

Happy Cutting! If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

As a producer of gasket material, a very common question we get asked is some variation of “How can you cut this?”. It is a great question, and one that should be asked before you even attempt to cut your first gasket out. Different types of material call for different cutting technologies. Some material is universal enough to be cut on just about anything, and other material can really only successfully be cut a certain way. There’s no need to struggle through a long period of trial and error…just keep reading to narrow your list of technologies to try.

Rule Die

Steel rule dies are the most common form of “die cutting”. They have worked extremely well cutting “soft” materials such as rubber, foam, cork, fiber, and others for many years. Metal-reinforced materials are also commonly cut with steel rule dies, sometimes with different rule, ejection rubber, and matting material.

Waterjet

Waterjet cutting works well with many homogeneous materials. For perforated (tanged) core products, it can be a challenge, as the water stream changes direction when hitting the core, resulting in blow-off, which removes the facing. For solid core items, waterjet cutting works well.

Laser Cut

Laser cutting has proven to be an excellent process to cut metal-reinforced materials. It works in most cases, except where a layered facing is used, where high heat can peel layers. Cutting graphite with a laser is possible, but takes some practice and adjustment to get a clean cut.

Hard Tool

Hard tooling is also called Class A dies or matched male/female tooling. This is the best method of cutting anything, and provides a clean cut with crisp edges and minimal deformation of the product. It is the best method for cutting metallic products in high volume.

Flash Cut

Flash cutting features a programmable, oscillating knife blade cutter on a bed-type table. This method works very well for small volume production of any size part, and is especially preferred for large parts in lieu of building a cutting die. Most materials cut well with this method, even metal-reinforced items of tang or solid core, except for Armor-clad designs.

Thanks, But What’s the Cost?

Since we’re not a fabricator, we aren’t in a position to tell you how much it actually costs to cut with these methods, but we do have a fairly good idea of where they fall on the scale from relatively inexpensive to relatively expensive. However, remember that it is important to look at value, not cost. (The same principles hold true – be sure to read How Much Should Gasket Material Cost?.)

Cut It Out!

There are a lot of great technologies out there and we’ve seen success with all 5 of these in different materials on our product line. If you don’t produce your own gasket material, one of the most important things you can do is ask your gasket material supplier how they would recommend you cut the material. It sure beats wasting time and precious material!

Happy Cutting! If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.