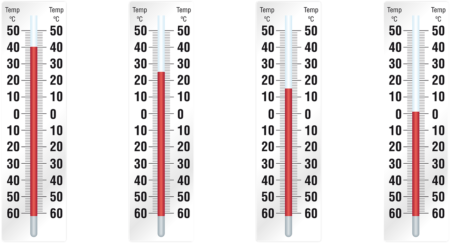

We have recently been looking at applications that have uneven temperature exposure around the perimeter of gaskets. In some cases, one side sees more heat than the other. From the material manufacturing side, there are a number of things we can do.

We have recently been looking at applications that have uneven temperature exposure around the perimeter of gaskets. In some cases, one side sees more heat than the other. From the material manufacturing side, there are a number of things we can do.

First of all, it is important to understand why you are seeing uneven temperature exposure. Unfortunately, this happens most of the time during testing (or even field use) as opposed to the design phase. Due to this, you need to sometimes design a material after the fact.

Whether your application was designed that way, or if it is a function of the application running under normal (or sometimes abnormal) operating conditions, your trusted gasket material supplier can help you find a material that will meet your requirements.

Drilling Down

Once you understand why you are seeing the uneven temperature exposure, it is time to find a material that can handle it. When you are dealing with composites, the success or failure of your material is going to be in the facings. Here are some conditions that you may be working with:

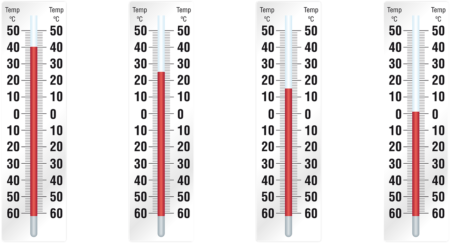

1. Insulative Issues

In these situations, we can use insulative facings to design the gasket to resist thermal conductivity as much as possible. Not only do you want to keep the heat out, you may be designing to keep the heat in. When a heat shield isn’t practical, you can sometimes insulate with your gasket.

2. Peak Temperatures

We can select facings to deal with the peak temperatures in a localized area by making the entire gasket resistant to this effect. We can also work with OEM engineers to identify temperature exposure so the proper facings can be chosen.

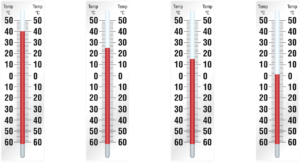

3. Heat Soak

Sometimes, the steady state operating conditions are not the extreme. The design conditions must also incorporate “heat soak”. This happens once an engine is shut off. With the cooling system no longer operating, the heat of the engine parts flows into other parts, thus elevating the temperature of parts that were not designed for that type of heat exposure. Gaskets and seals must be designed for this. It is possible to have fluid seals like valve cover gaskets, exposed to higher temps due to this “heat soak” mechanism, thus requiring a higher temp material than originally expected.

One of the perks in working with composites in these situations is the ability to utilize two different facings to survive the conditions on each side of the joint. If you can’t find a single material to meet the requirements, work with two!

Challenge Accepted

As a company that engineers and manufactures gasket materials, we are always looking for opportunities to create custom solutions for gasket applications that exist in challenging conditions. Working with composites, we have the ability to manufacture exactly what is necessary to meet the requirements for your application, and we are always looking for feedback from the market on what needs are not being met. With new applications being developed every day, there will continue to be unique challenges that design engineers are trying to find a solution for. If this sounds like you, don’t hesitate to reach out to a trusted gasket material supplier to look for answers.

If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

We have recently been looking at applications that have uneven temperature exposure around the perimeter of gaskets. In some cases, one side sees more heat than the other. From the material manufacturing side, there are a number of things we can do.

First of all, it is important to understand why you are seeing uneven temperature exposure. Unfortunately, this happens most of the time during testing (or even field use) as opposed to the design phase. Due to this, you need to sometimes design a material after the fact.

Whether your application was designed that way, or if it is a function of the application running under normal (or sometimes abnormal) operating conditions, your trusted gasket material supplier can help you find a material that will meet your requirements.

Drilling Down

Once you understand why you are seeing the uneven temperature exposure, it is time to find a material that can handle it. When you are dealing with composites, the success or failure of your material is going to be in the facings. Here are some conditions that you may be working with:

1. Insulative Issues

In these situations, we can use insulative facings to design the gasket to resist thermal conductivity as much as possible. Not only do you want to keep the heat out, you may be designing to keep the heat in. When a heat shield isn’t practical, you can sometimes insulate with your gasket.

2. Peak Temperatures

We can select facings to deal with the peak temperatures in a localized area by making the entire gasket resistant to this effect. We can also work with OEM engineers to identify temperature exposure so the proper facings can be chosen.

3. Heat Soak

Sometimes, the steady state operating conditions are not the extreme. The design conditions must also incorporate “heat soak”. This happens once an engine is shut off. With the cooling system no longer operating, the heat of the engine parts flows into other parts, thus elevating the temperature of parts that were not designed for that type of heat exposure. Gaskets and seals must be designed for this. It is possible to have fluid seals like valve cover gaskets, exposed to higher temps due to this “heat soak” mechanism, thus requiring a higher temp material than originally expected.

One of the perks in working with composites in these situations is the ability to utilize two different facings to survive the conditions on each side of the joint. If you can’t find a single material to meet the requirements, work with two!

Challenge Accepted

As a company that engineers and manufactures gasket materials, we are always looking for opportunities to create custom solutions for gasket applications that exist in challenging conditions. Working with composites, we have the ability to manufacture exactly what is necessary to meet the requirements for your application, and we are always looking for feedback from the market on what needs are not being met. With new applications being developed every day, there will continue to be unique challenges that design engineers are trying to find a solution for. If this sounds like you, don’t hesitate to reach out to a trusted gasket material supplier to look for answers.

If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.

We have recently been looking at applications that have uneven temperature exposure around the perimeter of gaskets. In some cases, one side sees more heat than the other. From the material manufacturing side, there are a number of things we can do.

First of all, it is important to understand why you are seeing uneven temperature exposure. Unfortunately, this happens most of the time during testing (or even field use) as opposed to the design phase. Due to this, you need to sometimes design a material after the fact.

Whether your application was designed that way, or if it is a function of the application running under normal (or sometimes abnormal) operating conditions, your trusted gasket material supplier can help you find a material that will meet your requirements.

Drilling Down

Once you understand why you are seeing the uneven temperature exposure, it is time to find a material that can handle it. When you are dealing with composites, the success or failure of your material is going to be in the facings. Here are some conditions that you may be working with:

1. Insulative Issues

In these situations, we can use insulative facings to design the gasket to resist thermal conductivity as much as possible. Not only do you want to keep the heat out, you may be designing to keep the heat in. When a heat shield isn’t practical, you can sometimes insulate with your gasket.

2. Peak Temperatures

We can select facings to deal with the peak temperatures in a localized area by making the entire gasket resistant to this effect. We can also work with OEM engineers to identify temperature exposure so the proper facings can be chosen.

3. Heat Soak

Sometimes, the steady state operating conditions are not the extreme. The design conditions must also incorporate “heat soak”. This happens once an engine is shut off. With the cooling system no longer operating, the heat of the engine parts flows into other parts, thus elevating the temperature of parts that were not designed for that type of heat exposure. Gaskets and seals must be designed for this. It is possible to have fluid seals like valve cover gaskets, exposed to higher temps due to this “heat soak” mechanism, thus requiring a higher temp material than originally expected.

One of the perks in working with composites in these situations is the ability to utilize two different facings to survive the conditions on each side of the joint. If you can’t find a single material to meet the requirements, work with two!

Challenge Accepted

As a company that engineers and manufactures gasket materials, we are always looking for opportunities to create custom solutions for gasket applications that exist in challenging conditions. Working with composites, we have the ability to manufacture exactly what is necessary to meet the requirements for your application, and we are always looking for feedback from the market on what needs are not being met. With new applications being developed every day, there will continue to be unique challenges that design engineers are trying to find a solution for. If this sounds like you, don’t hesitate to reach out to a trusted gasket material supplier to look for answers.

If you are interested in subscribing to Sealed-In’s blog posts, email sales@mtigasket.com.